AutoPIPE - AutoPIPE at-a-glance

Modeling

- Single line, wire-frame and solid render drawing modes

- CAD style single, double, or quad view ports

- Vertical axis (Y or Z) can be switched on the fly

- On-screen distance calculator for accurate coordinate checks

- Built-in valve actuator for more accurate valve modeling

- Segment management: reverse, split, join, and re-order segments

- CAD line class and line numbers

- Connectivity checker to avoid model disconnects

- English, metric, SI, and user-defined units

- Extensive ANSI/ASME, DIN, EN, JIS, GD, GB, GOST, and GRP/FRP standard piping component and material libraries

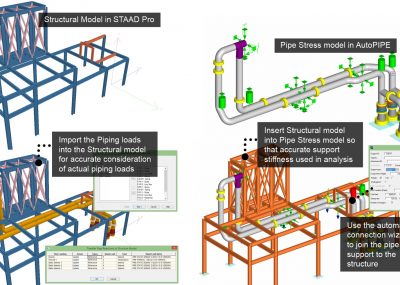

- Structural steel modeling using structural databases for 17 countries

- Expansion joint modeling with tie rod assemblies

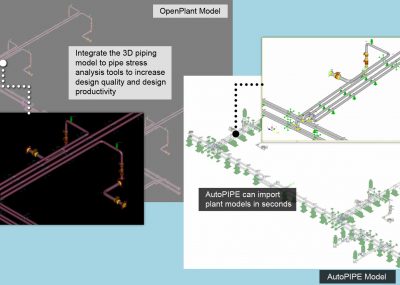

- Model import from AutoPLANT®, PlantSpace®, OpenPlant®, MicroStation®, Excel®, AutoCAD®,Intergraph PDS®, SmartPlant®, Aveva PDMS®, CADWORX®, SolidWorks®, Inventor®, Plant 3D, CATIA®, and PlantFLOW®

- PIPELINK bi-directional integration with STAAD.Pro

- Automatic stress isometric generation in DXF, DWG or DGN formats with engineers mark-ups

- Model geometry data export into AutoPLANT®, MicroStation®, and AutoCAD®

- Automated ring main wizard

- Automatic ASCE soil calculator

Dynamic Analysis

- Time history dynamic analysis with ground motion

- Mode shapes, accelerations, and natural frequencies

- Harmonic load analysis

- Uniform & MSRS response spectrum and shock spectra

- Multiple spectrum enveloping

- NRC spectra and code case N411 (PVRC) damping and spectra

- NUREG.CR-1677, CR-6414 and CR-6049 benchmarks

- Automatic mass discretization

- Missing mass and ZPA correction

Piping Codes

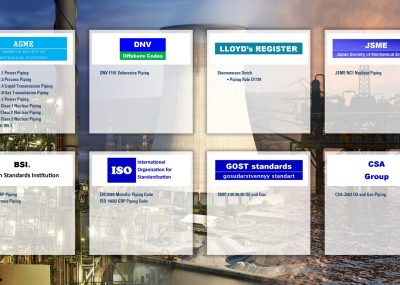

- ASME B31.1 (multiple years), B31.3, B31.4, and B31.8

- ASME Sec. 3, Class I, II, and III (multiple years from 1972)

- European Standard Metallic Industrial Piping EN13480

- B31.4, B31.8, B31.4 Offshore, B31.8 Offshore and CSA_Z662 Offshore codes, DNV OS F101 offshore code

- Canadian CAN/CSA–Z662

- British Standard BS 806, BS 7159 (GRP piping code)

- FRP ISO 14692

- ASME N755 HDPE Code Case

- Russian SNIP 2.05.06-85 Oil and Gas

- Swedish Piping Code (SPC) Method 2

- Norwegian Det Norske Veritas (DNV) and TBK 5-6

- Dutch Stoomwezen D1101

- Japanese KHK, MITI class 3, JSME NC1-PPC and General Fire Protection code

- French RCC-M and SNCT

Analysis

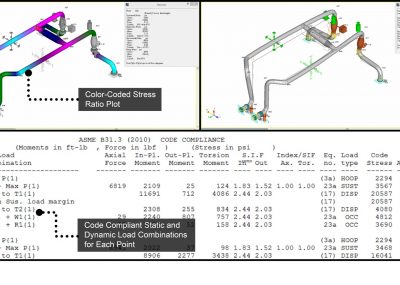

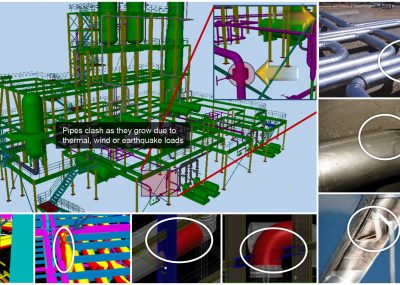

- Unlimited static analysis to examine different loading scenarios including hot modulus for any combination of 100 thermal, 10 seismic, 10 wind, and 50 dynamic load cases.

- Automatic generation of wind profiles per ASCE and UBC guidelines

- Wave loading and buoyancy for offshore applications

- Hydrotest analysis with locking spring hangers

- Fluid transient utilities for water and steam hammer plus relief valve load analysis

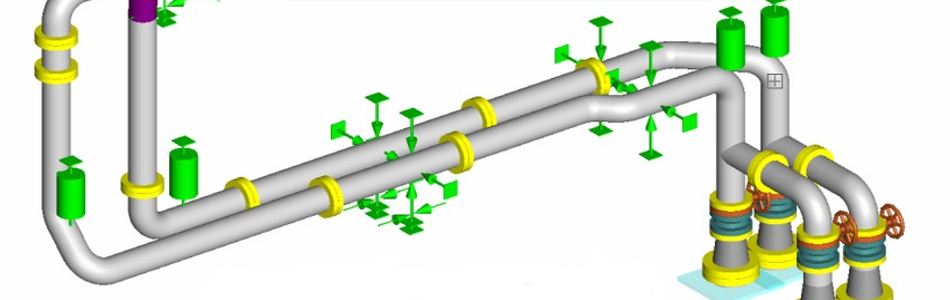

- Automatic spring hanger sizing from 27 manufacturers

- State-of-the-art nonlinear support gap, friction, yielding, and soil interaction with advanced features of seismic wave propagation, overburden and settlement loads, and stresses to ASCE, AWWA, and ASME

- Thermal stratification bowing analysis

- Thermal transient analysis (TTA), fatigue and high energy/leakage design for ASME Class 1

- Seismic static and response spectra load generator to IBC, Euro, ASCE, Indian, Spanish, Mexican, and Chinese, standards

- Ec/Eh ratio applied to expansion stresses for any piping code

- Integrated flange loading analysis per ASME VIII Div 1 and 2, ASME III App XI, and ANSI B16.5

- Nozzle flexibility analysis per API 650 App. P, ASME Class 1, WRC 297 and Biljaard methods

Input and Results

- Results saved to Microsoft Access MDB file for post-processing

- Automatic or user-defined load combinations grid

- Automated batch processing

- Maximum intermediate stresses

- Reference point for manufacturer equipment loading reports

- Rotating equipment calculations to API 610, NEMA and API 617, and user-defined standards

- Results can be filtered and sorted by stress, deflection, or load criteria